Airdomes or pneumatic structures were patented in 1917 by a British engineer for the construction of a military hospital, one Frederick William Lanchester.

Due to some fires and failures, however, the full implementation and actual use of pressostatic structures did not occur until 1946 in Alaska, used as a shelter for radar equipment.

Since that time, so-called airdomes began to be widely used in America for the purpose of quickly establishing covered areas such as warehouses, war weapons assembly areas, vehicle and aircraft maintenance workshops, mobile hospitals and more.

What is, in technical terms, a pressure structure?

A pressure balloon is a “building” whose materials are held in place by aerostatic pressure, that is, by air pressure.

They are, therefore, highly resistant shaped inflatable covers whose shape is determined by the difference in pressure between the inner shell and the atmospheric pressure, thus representing an extremely efficient structural system in terms of load-bearing weight ratio.

Overpressure in the structure is maintained by a main inflation unit, which is integrated with the heating system.

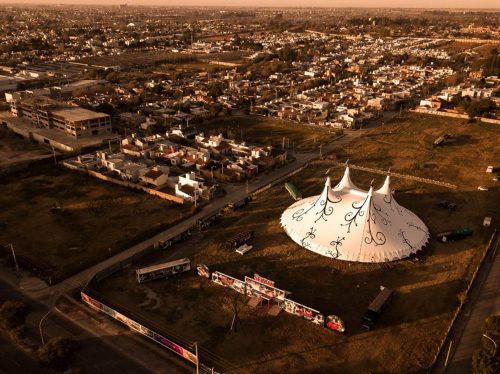

The pressostatic roof is essentially formed by a double or triple pvc roofing membrane with a central semi-cylindrical shaped tunnel, closed at both ends by two positive total curvature sails.

The material used for the pressure structures is a high-tenacity polyester fabric, coated with PVC-based compounds on both faces, treated against fungus and mold, UV-resistant, whose technical characteristics of weight, tensile strength and tear strength are suitable for use and given in the material technical tables.

The closing membrane of the pressostatic cover can be single or double.

In the latter case, some of the air that is fed into the structure by the blower is conveyed between the 2 membranes, in turn keeping them under pressure and thus detached from each other, creating an air gap. This bearing makes it possible to contain heat loss, hence energy expenditures related to winter operation, when the heat generator is used in addition to the blower to keep the structure warm.

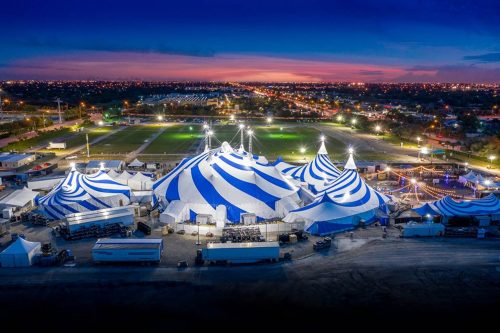

Pressostatic balloons are now highly popular in the sports sector (swimming pools, tennis courts, padel courts, volleyball courts, golf courses, soccer fields, riding arenas) because of their ease of assembly and disassembly and because they can cover particularly large areas.

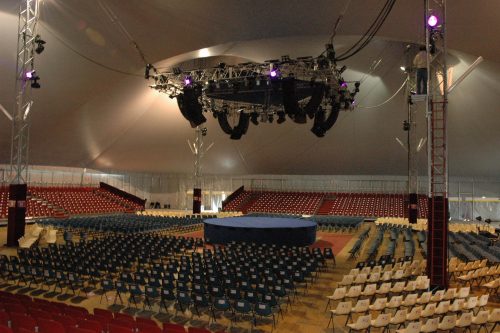

Because of these features, in addition to their uses for sports, pressure structures can also be used as storage areas, warehouses, or to create covered places for rallies, events, and festivals.

Projects of pressure structures made by Canobbio Textile.

Canobbio Textile specializes in the construction of pressostatic structures and has completed numerous sports roofing projects: pressure structures for soccer e pressostructures for sports.

All facilities are designed and installed complete with LED lighting systems specific to different sports activities.

The stability of the pressostatic structure, even in the event of a power failure, is ensured by an emergency secondary unit with a diesel engine, connected to the pressure sensor and an anemometer that detects the wind speed by automatically intervening.

The control of proper operation is processed by a PLC, which is programmed to manage the operation of the pressure structure and economize operating costs with the ability to send data and any anomalies via GSM and limit the presence of the sports facility manager.