A history of innovation and research

In 1926 Federico Canobbio laid the foundations for a company that went on to carve itself a history of technological excellence within its sector. The company first manufactured agricultural canvas and saddlery items to satisfy the market’s requirements at that time, before investing in textiles in the 1950s under the stewardship of Giuseppe Canobbio and his brother Francesco. With remarkable intuition and determination, despite the inherent difficulties of all forms of innovation and the absence of suitable materials, Giuseppe Canobbio began his application of a revolutionary covering system, which now exists in a variety of forms.

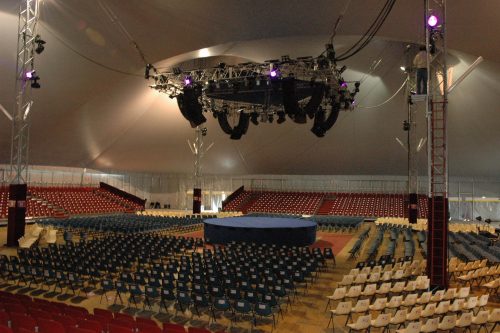

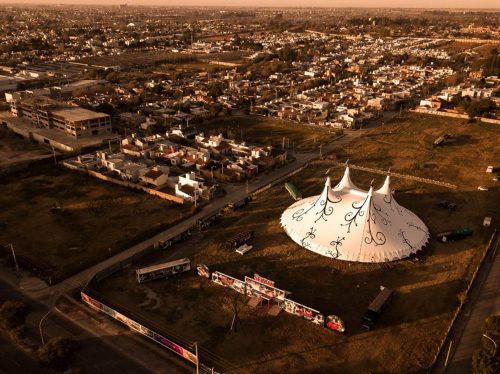

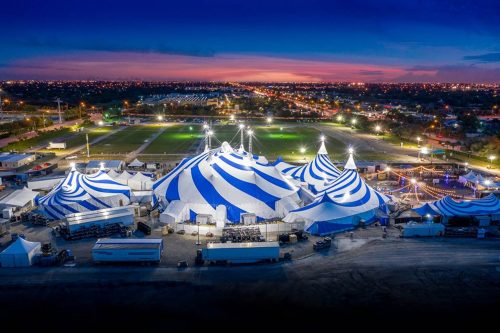

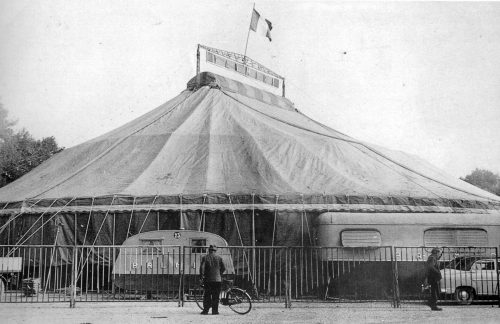

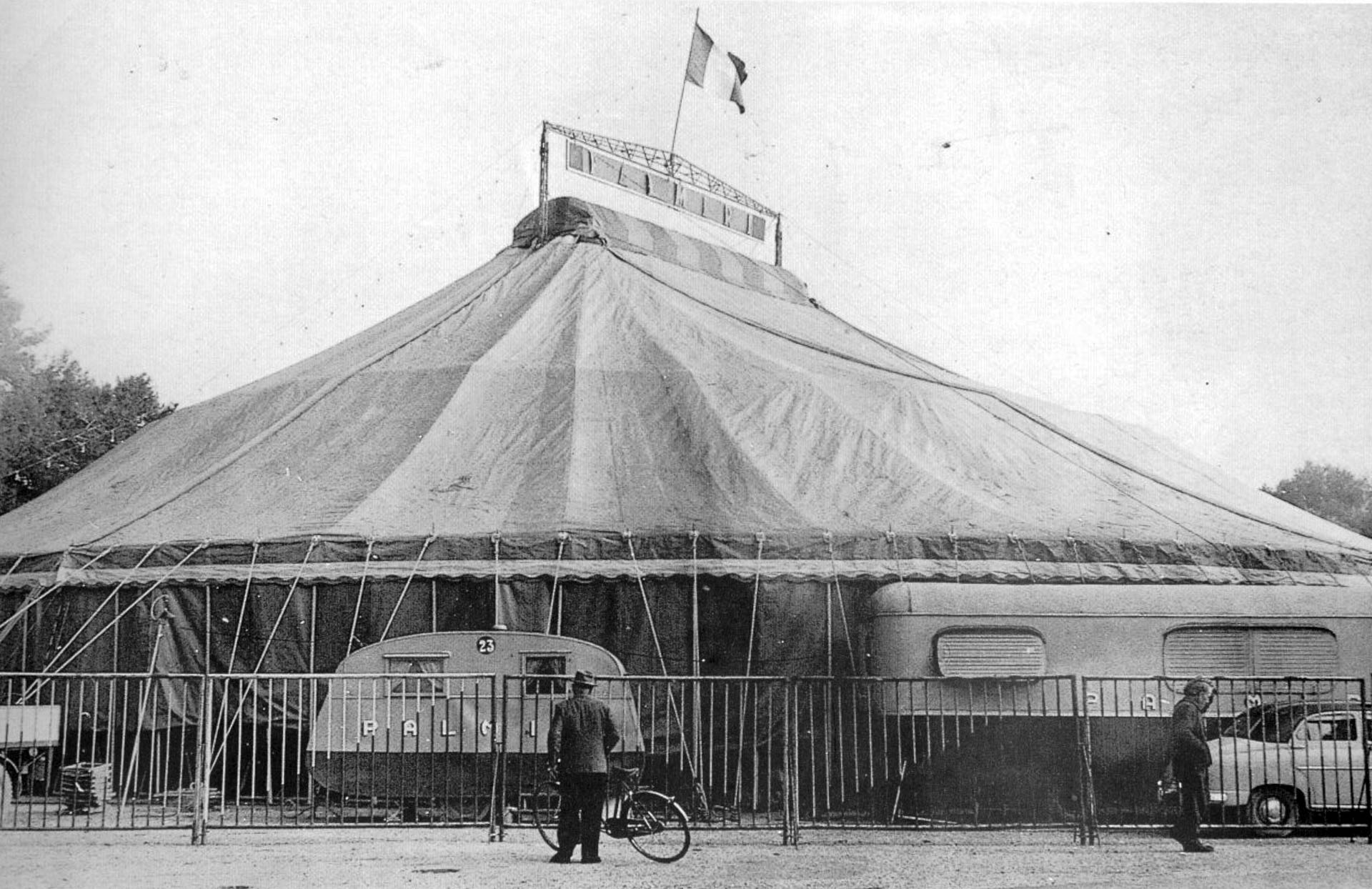

The result was the first circus tent, which the company’s new factory, in the centre of the town of Castelnuovo Scrivia, present- ed as a first example of a lightweight structure. Hemp and cotton were the materials available at the time, while the existing production method was sewing by machine. Canobbio set about optimising processing products and methodologies to ensure that the structure was perfectly functional and totally safe for those using it.

The company’s proven ability in reaching these objectives was an important step, but its research did not stop here. New materi- als and production systems were researched and in time, this extensive work led to Canobbio being the first Italian company to adopt synthetic fabrics.

PVC coated nylon and polyester with continuous hot welding were identified as resistant and durable materials, and a new generation of coverings with lightweight structures gave the company a position of global leadership in the field of circus tents on the back of demand for its products from European markets.

The company’s original artisanal production facilities in Castelnuovo were no longer sufficient, as more space and new machinery were now needed.

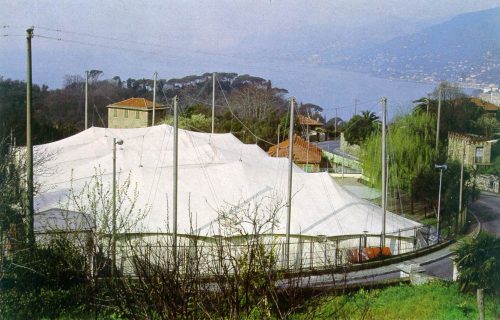

As a larger and more modern factory was be- ing built, the company’s technological evolution proceeded. The first significant results it reached in the 1970s involved the use of high frequency microwaves for the welding of PVC fabrics and the production of pneumatic structures for covering tennis courts.

The development of high-performance textile materials and computer-assisted structural analysis opened new application areas and enabled the creation of more complex covering systems.

Construction processes and practices increasingly employed this tool due to its graphic and calculation capabilities resulting in new design methodologies.

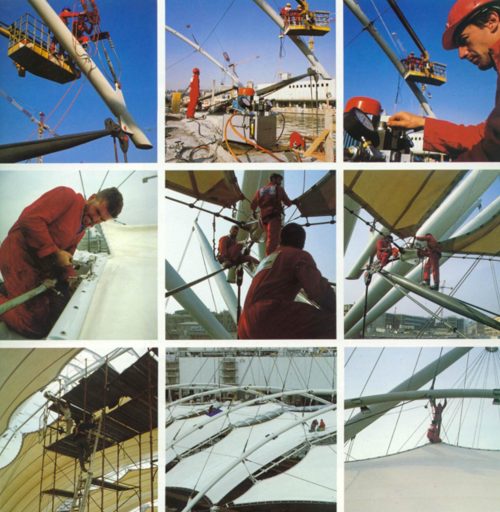

The company took its first steps in the field of ten- sile structures by drawing on the experience of Ger- man experts, resulting in a collaborative partnership with engineer Harald Mühlberger and his firm, IPL, in the design of tensile membrane structures.

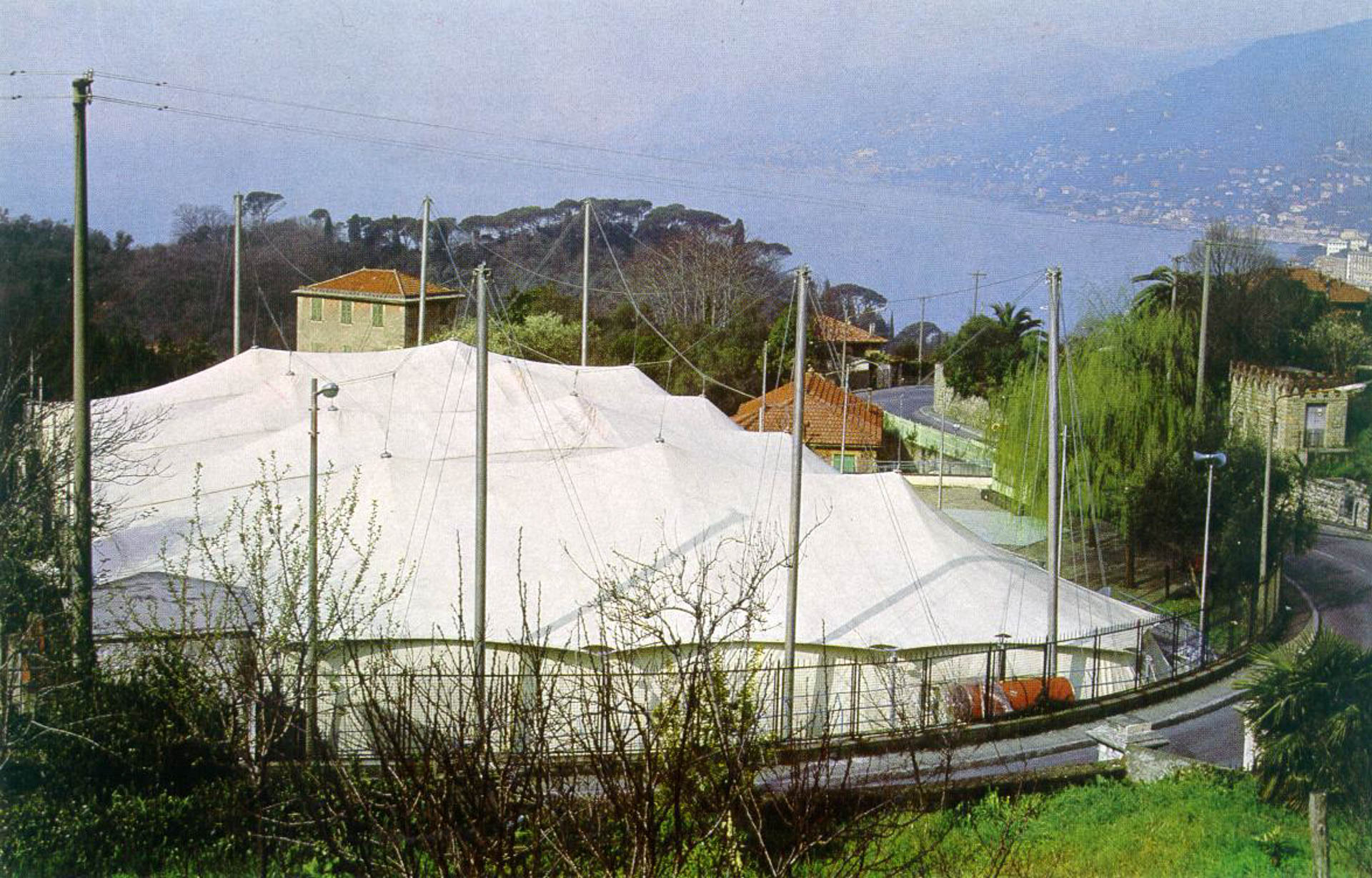

This cooperation resulted in significant projects like the covering of the municipal swimming pool in Camogli, that was produced with a sophisticated rope-supported system enabling the textile mem- brane roofing to be moved quickly.

The third generation of the Canobbio family – broth- ers Federico and Roberto and their cousins Renzo and Alberto – joined the company in the early 1980s, as new lightweight structure applications and pro- duction techniques came to fruition. The company was also the first in Italy to use glued laminated tim- ber to support the covering membrane and a special welding line for PTFE coated glass fibre fabrics.

In the 1990s Canobbio made another decisive step forward with the upgrading of its technical and sales teams and through the development of a network of professional relations with leading designers and the most qualified buyers. There were numerous av- enues to explore and develop: aside from improving the resistance, durability, fire behaviour, insulation and cleaning ability of existing fabrics, a number of new applications were being developed, with the use on an industrial scale of new experimental materials, such as mono-fibre or highly resistant and completely recyclable fabrics. These technological improvements also enabled tensile membrane structures to be extended to new areas: residential, ecological and environmental, and air-condition- ing.

This continual evolution was pursued through partnerships with design firms, universities, active participation in conferences and Italian working groups involved in drafting European legislation for the sector. The company continued its process of evolution by investing in automation to further improve its qual- itative standards and develop additional know-how in the sector of lightweight coverings with the use of materials such as ropes, polycarbonate, structural glass, stainless steel and light alloys.

Towards textile architecture

Since the 1980s the technical evolution of mate- rials and calculation systems paved the way for new applications of textile membrane structures, which became fully fledged features of architectural design as opposed to ‘mere’ coverings.

The term ‘textile architecture’ began to be used and Canobbio cooperated with the leading international designers to create innovative solutions with a high aesthetic impact.

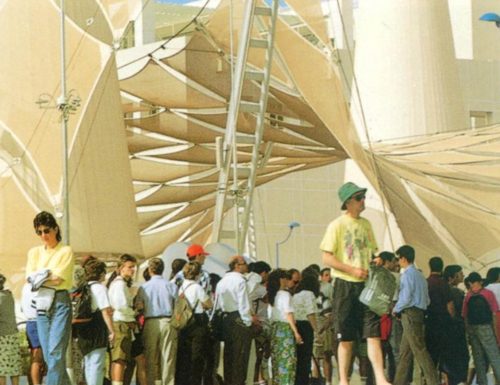

The 1990s and the first decade of the new millennium represented a period of experimenta- tion, with a series of landmark projects: from Bigoin Genoa to the Valencia Expo, from multi-functional structures to the Zenith, from artistic installations to the new generation of sports complexes.

Canobbio embraced this phase of radical change with great zeal and increasing levels of investment. Eventually, it made the precise choice of recon- figuring the company to offer even more support and technical services to designers and its major customers.

This led to the founding in the spring of 2014 of Ca- nobbio Textile Engineering: a new company capable of meeting the needs of a complex market thanks to a more streamlined organisational structure, a greater focus on design and technological develop- ment and an even more international outlook.

Roberto Canobbio, technical manager of Canobbio Textile Engineering explains this process:

“In the last two decades the company has focused increas- ingly on textile architecture and has made precise choices in terms of both development and its target market. We have abandoned certain types of prod- ucts and introduced others, with the aim of offering excellent technological solutions to highlight the structural value of our products. The new company was an important step in this regard, because it enabled us to reconfigure

our organisation in a more modern and contemporary fashion and to enhance our contribution to the major projects we have

been privileged to work on alongside the world’s leading architecture firms. Today Canobbio is a profoundly different company than it was in the past and we are extremely proud of everything we have achieved in the past ninety years. It has been a process of continual growth, characterised by experimenta- tion and research, tremendous enthusiasm and hard work. When I look back, I really think we have achieved something important for the sector. Canobbio

Textile Engineering combines the experience and tradition of Canobbio Spa with an efficient and modern organisational structure, offering a qualified and professional team with the know-how to take on the challenges of the future”.

This future begins with the company’s most recent projects, particularly its work for Expo 2015, includ- ing the project for the covering of the China Pavilion overseen by Simpson Gumpertz & Heger Inc. (SGH). This covering was designed as an element floating above the ‘Field of Hope’ with natural light and elegant forms that combine the exhibition spac- es with a platform.

The architectural concept of the covering was con- ceived as a wooden structure and was inspired by a series of landscapes, featuring cities as well as rural environments.

In particular, terracing was created through sharp cuts of the forms, which were connected lengthwise to the urban and rural landscapes by purlins forming a flat surface. One of the features of traditional Chinese constructions consists in elegant forms obtained through the use of curved surfaces. The importance of aesthetics in the Chinese Pavilion’s architecture is underscored at the north and south ends of the covering, which appear to be gently suspended. A mixed wooden and steel structure was designed to enable natural lighting to pour into the vast public spaces within the Pavilion. The project solution had to create huge spaces and, at the same time, include efficient and elegant structural forms.

Moreover, a great deal of importance was placed on the production sequence, especially consid- ering the time required for installation which was very limited. An eco-friendly bamboo panel system was also designed based on the undulating sur- face of the roof. This bamboo panel system was configured in such a way that the exhibition spaces benefited from natural light.

“Other projects are underway – concludes Roberto Canobbio – and through partnerships with interna- tional researchers and universities, we are continu- ing our research on materials and new solutions.

Just as it was in the past, technological innova- tion represents the cornerstone of our business, because it is only through increasingly high-per- formance and advanced solutions that we can maintain our reputation as innovators and continue to be a benchmark for this exciting sector”

WE HAVE CARRIED OUT PROJECTS WITH