-

Place

Civitavecchia (RM)

-

Year

2009

-

Architectural Project

Ing. Marco Forlini / Canobbio Textile

-

Membrane Project

Canobbio Textile

-

Area

10.000 m²

-

Textile

PVC polyester

-

Type

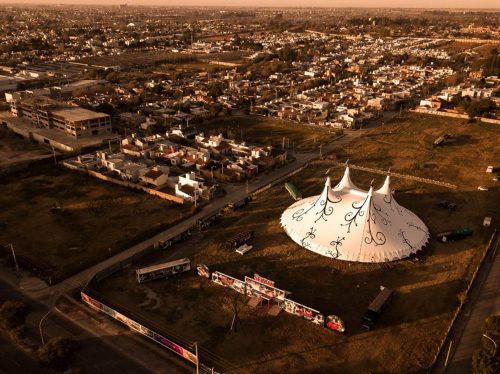

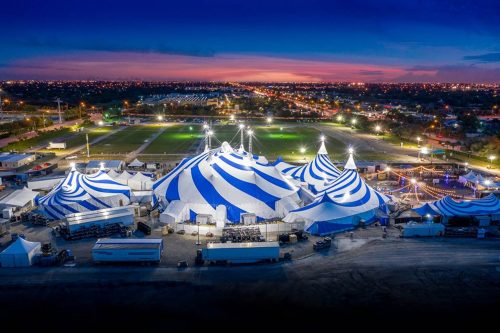

Special textile structure for Civitavecchia cruise terminal

-

Canobbio Textile Services

Glulam structure, supply and production of membranes, fixing and tensioning systems, heating system, lighting system, installation.

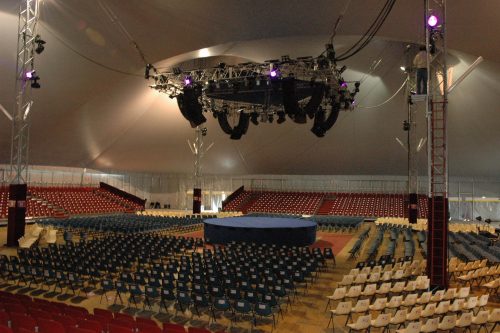

Civitavecchia Cruise Terminal

The textile with support made of glulam arches is the combination with the greatest aesthetic value. Here, the technique of processing wood with glulam is joined with a luminous cover jacket, made with the characteristic “saddle-like shape” of the tensile structures.

The considerably low construction times and the costs with respect to metal structures make this type of structure easy to use for sports facilities in general.

However, the use of this type of cover is not limited only to sports fields but, given the greater aesthetic value, it is increasingly used in civil/industrial fields like in the case of the 2 covers designed, built and installed for the Civitavecchia cruise terminal.

The first Tensile wood was made using the standard double membrane technology with obscuring outer membrane. In addition, it is rather large given that it measures 36 m x 132 m for a total covered surface measuring 4,620 m2.

Measuring 20 m x 150 m, the second structure was instead made using our ENERGY-T technology which maintains a constant distance between the two layers on the whole cover. The air treated inside the two layers increases the insulating capacity ensuring high energy efficiency performance during heating and cooling. Besides climatic conditions, applied to wooden structures, this ENERGY-T system allows cost-effective solutions from a management point of view.

Saving is also a result of using heating systems that operate with condensing boilers and therefore recovering the heat of the fumes.

As a matter of fact, the ENERGY-T technology offers 25% saving compared to conventional covers.