ETFE and PTFE are two materials increasingly used in the roofing of buildings, sports facilities, facades, archaeological sites and more.

They are sometimes mistakenly confused and interchanged with each other, or even considered the same thing by laypeople, but they are actually two very similar materials but composed of two different types of polymers, each with its own specific characteristics.

What are the differences between ETFE and PTFE?

The main difference between ETFE and PTFE lies in the chemical composition.

ETFE stands for Ethylene-Tetrafluoro-Ethylene, a thermoplastic polymer containing fluorine atoms, which, due to their exceptionally strong bonding, result in a transparent plastic material capable of withstanding high levels of thermal stress and chemical aggression.

The ETFE film material is formed directly from the material and has good durability, ease of cleaning and stability. Being a film, it does not have a fabric core and is currently the most advanced in the world.

PTFE, which stands for Poly-Tetrafluoro-Ethylene, is a chemically inert material that uses glass fiber as the base material to form a membrane. PTFE is also characterized by excellent durability, mechanical strength, flexibility and ease of cleaning.

ETFE is resistant to a temperature range of -70℃ to 220℃, while PTFE has a slightly higher range of -80°C to 260°C.

The two material’s chemical and corrosion resistances are very similar, as is its resistance to weathering, while ETFE’s resistance to creep and compression are better than that of PTFE.

Both materials are characterized by their light weight and ability to absorb large amounts of infrared light, a quality that can be exploited to improve a building’s energy consumption. In addition, both ETFE and PTFE are found to be immune to ultraviolet rays, pollution and other environmental weathering, including sea spray, and thus are distinguished by their long service life.

The materials have been extensively studied and tested in laboratory and field environments, concluding that no loss of strength or discoloration of ETFE and PTFE covers has occurred over time.

Among the advantages of ETFE are its high transparency: it can transmit up to 95 percent of outdoor light and has been chosen for projects such as stadiums with grass surfaces, where full-spectrum natural light and light transmission are essential to support plant growth.

ETFE film has higher light transmission and better chemical resistance than PTFE film, along with strong resistance to natural aging.

In contrast, because ETFE film is formed directly from plastic without a substrate, its tensile strength and tear strength do not reach the levels of those of PTFE film.

Regarding the flame-retardant performance of ETFE membrane and PTFE membrane, both of them can reach B1 level, which is that of totally flame-retardant materials.

It is clear, then, that although they are two similar materials, ETFE and PTFE also have important differences to consider before designing and installing a cover.

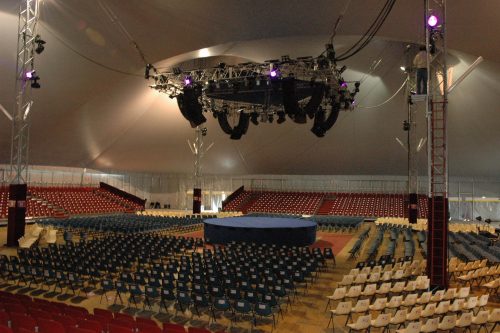

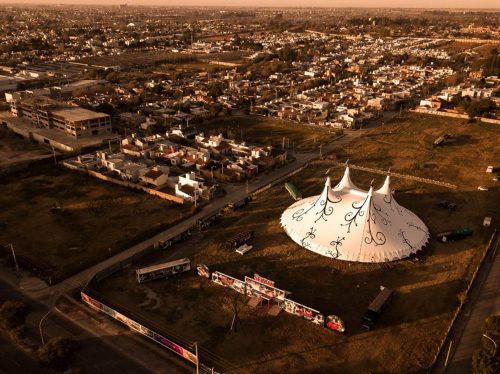

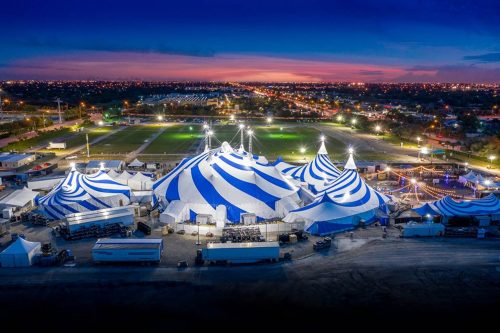

Through its experience around the world, Canobbio Textile has designed and manufactured numerous covers in both ETFE and PTFE, making the most of the advantages of these two materials as needed.